Unlocking Aerospace Excellence: Flight Test Instrumentation Takes Flight

Blue Hat Solutions gives end to end service for Flight Test Instrumentation with the purpose to gather accurate and comprehensive data during the testing and evaluation of an aircraft’s or new integration components performance, systems, and components. Flight test instrumentation involves the installation of various sensors such as accelerometers, linear and rosette strain gauge, data acquisition systems, and other instruments on an aircraft to capture real-time data during flight operations.

Key Objectives of flight test instrumentation:

Performance Evaluation: Flight test instrumentation allows for the measurement and evaluation of an aircraft’s performance parameters, such as airspeed, altitude, rate of climb, fuel consumption, and range. This data helps BHSPL engineers to assess the aircraft’s capabilities, validate performance specifications, and identify areas for improvement, particulary when new role equipment or any other modification is being tested for the first time on an existing platform.

Systems and Component Testing: Flight test instrumentation is used to assess the performance and functionality of various systems and components within the aircraft. It enables BHSPL engineers to monitor and analyze the behavior of systems such as avionics, engines, flight controls, landing gear, and environmental control systems. This testing ensures that these systems operate safely and effectively under real-world flight conditions.

Structural Analysis: Instrumentation is used to measure the structural response of an aircraft during flight and compare the analytical and qualification test results against actual performance in air. Strain gauges, accelerometers, and other sensors are installed at critical points to monitor loads, stresses, vibrations, and other parameters that help evaluate the structural integrity and performance of the aircraft.

Aerodynamic Analysis: Flight test instrumentation is crucial for study and validation of the aerodynamic predictions done by CFD Analsis. Pressure sensors, airflow sensors, and other instruments are employed to measure air pressures, flow velocities, lift, drag, and other aerodynamic forces. This data aids in validating and refining aerodynamic models, optimizing aircraft, role equipment or new store performance, and improving handling characteristics.

Flight Control System Evaluation: Instrumentation enables the measurement and analysis of an aircraft’s flight control system response, stability, and control characteristics. This includes assessing control surface deflections, control system inputs and outputs, response to pilot commands, and overall flight handling qualities.

Safety and Certification: Flight test instrumentation plays a critical role in ensuring the safety and certification of aircraft or integration of a new store on an existing and proven configuration of a platform. It provides essential data for compliance with regulatory requirements, airworthiness standards, and certification processes mandated by RCMA / CEMILAC in India as well as other global regulatory bodies. BHSPL collects accurate and reliable data during flight testing, and engineers demonstrate the performance, safety, and reliability of the aircraft to regulatory authorities.

Flight test instrumentation allows engineers to collect empirical data that validates design assumptions, verifies performance claims, and identifies areas for improvement. The insights gained from flight testing help enhance aircraft performance, safety, efficiency, and reliability, leading to the development of better and more capable aircraft.

DATA AQUISITON SYSTEMS used for Flight Test Instrumentation by BHSPL

BHSPL employs Data Aquisition System (DAS) from DTSweb.

Using a small data acquisition system in flight test instrumentation offers several advantages, including:

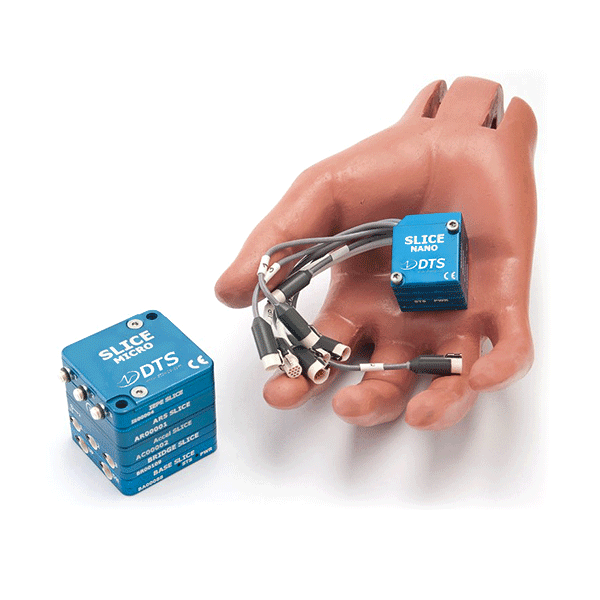

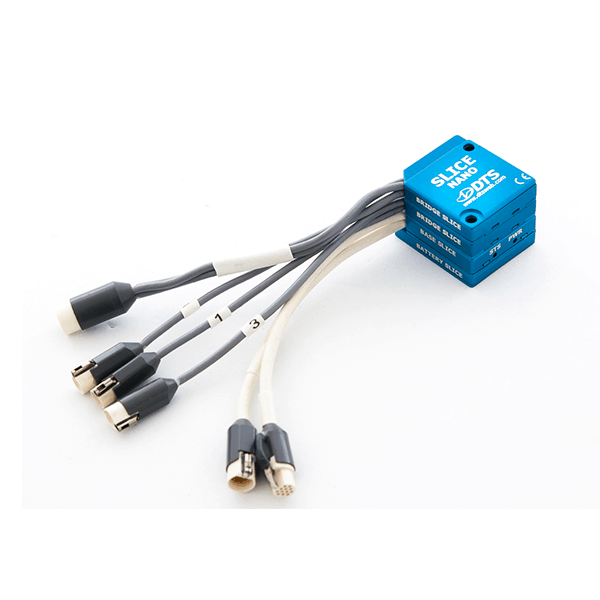

1. Size and Weight: Small data acquisition systems namely Slice 6 Air and Slice Nano are compact and lightweight, making them easier to install and integrate into an aircraft. Their smaller form factor allows for flexible mounting options and reduces the impact on the overall weight and balance of the aircraft, minimizing any potential interference with the test objectives.

easier to install and integrate into an aircraft. Their smaller form factor allows for flexible mounting options and reduces the impact on the overall weight and balance of the aircraft, minimizing any potential interference with the test objectives.

2. Versatility and Portability: Data acquisition systems are designed to be portable and versatile, allowing them to be easily deployed across different aircraft or test platforms. Their compact size enables flexibility in test configurations and facilitates quick setup and teardown, making them suitable for a range of flight test programs and environments.

3. Cost-Effectiveness: Our data acquisition systems along with support are cost-effective compared to larger, complex systems. They offer a streamlined set of functionalities tailored specifically for flight test requirements, eliminating the need for excessive features and reducing overall system costs. This cost advantage allows BHSPL to offer flight test instrumentation services at a very competitive price to our customers compared to the market rates.

4. Rapid Data Processing: Slice family of DAS systems are designed for efficient data capture and processing. They allow for rapid data acquisition and analysis during flight operations. This speed and responsiveness enable quicker feedback to the flight test team, facilitating prompt decision-making and adjustment of test parameters if needed.

5. Enhanced Data Integrity: With a smaller  system, there is reduced complexity and fewer potential points of failure, resulting in improved data integrity. The simplicity of the setup and signal conditioning helps to minimize signal degradation, noise interference, and data corruption, ensuring reliable and accurate data acquisition throughout the flight test campaign.

system, there is reduced complexity and fewer potential points of failure, resulting in improved data integrity. The simplicity of the setup and signal conditioning helps to minimize signal degradation, noise interference, and data corruption, ensuring reliable and accurate data acquisition throughout the flight test campaign.

6. Ease of Maintenance: Slice family of DAS systems have simple architectures and fewer components, leading to easier maintenance and troubleshooting. Their streamlined design translates to lower maintenance requirements and less frequent calibration or servicing, reducing downtime and enhancing overall system availability for flight testing.

The advantages in size, versatility, cost-effectiveness, rapid data processing, data integrity, and maintenance make Slice DAS along with BHSPL expertise to utilize them for many flight test applications makes a perfect choice when it comes down to capturing accurate flight test instrumentation data for any integration program.